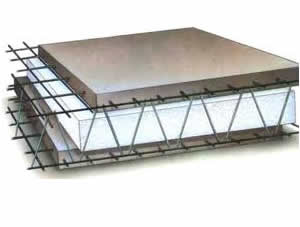

3D Panel Wall Structure

Foamed polystyrene insulating layer with the thickness of 100m/m in the center, steel wire truss coated with zinc of 3m/m(3.8mm) between the insulating layer is pinned at 2`` intervals, at both sides of which forms up at 5Cm X 5Cm(5Cm X 10Cm) intervals with the wire mesh coated with zinc of 3m/m(3.8mm) that is at fine-spun 50m(100m)intervals. So the whole points of contact in all steel wires is joined in a spot welding, which is a panel of 2.4m(4m) full length, 1.2m width, 60~200m/m thickness.

At the first time, it will be sprayed or hand plastered on the both sides in a thickness of 7m/m~10m/m, and finished with first coat and double second coat of 35m/m~30m/m thickness, which produces the structure with the total thickness of 12Cm~13Cm, the self-load of 120kg/m2, and the strong earthquake proofing.

Email: sales@3dpanels.org URL: https://www.3dpanels.org

Taibay Wire Panel Factory